Frequently Asked Questions

General questions

The Pitlock Principle

Not only the coded nut protects against theft but also the particularly designed spring washer. It anchors with our coded nut and locks the closure. In order to undo the system the Pit key is used. The Pit keys side panels press and turn the springs of the spring washer at the same time, a principle comparable to child safety locks on certain medicine bottles. Thanks to this principle on the one hand and to the chamfered coded nut on the other hand, pliers will not have a chance to break our system. In addition the conical security ring is pivoted so that it can not be cut by using force.

Pitlock is made of certified, high-quality and stainless steel and 10 Nm are more than sufficient (not the case for solid axles) to stick the hub incl. the bicycles fork.

Keep Your Bike From Being Stolen

Dos and Don'ts to make it more difficult for thieves to succeed

Dos

- Always mark your bicycle.

- Always lock your bicycle (even in hallways) to a sturdy object (a wooden garden fence, e.g. would not be very suitable...).

- Always choose carefully where you want to park your bicycle, it will determine its fate.

- Always look for a crowded place that is lit brightly to park your bicycle, e.g. in front of the nearest pub. The same applies to railway and bus stations.

- Always use all of the locking devices (PITLOCK security, caps, bars etc.) available.

- Always make sure to let the locking mechanism point downwards and leave as little space as possible between the lock and the bike, so the thief will not have any direct access to it.

- Always make sure to park and lock your bicycle in an upright position without giving the thief a chance to lay it down.

- Always shorten the PITLOCK axle as much as possible, so it will not stick out too much.

Don'ts

- Never park your bicycle near locations that tell the thief for how long the bike will be left unattended. One example would be outside of a cinema. Here thieves can be certain to have time until the ending of the movie.

- Try to avoid parking your bike outsides overnight.

- A wheel lock is not secure enough, even if you are only absent for a short time. Consider purchasing the PITLOCK backups that will secure your removable bicycle parts.

- Never put the lock close to the ground, since that position makes it easier for thieves to smash it open with a hammer.

- Never leave any tools with your bicycle! Although these will be helpful when having a flat tire etc., but they will also be helpful for thieves.

- Never leave your PITLOCK key with your bike.

Secure your removable bicycle parts, such as the wheels, the seat, the ahead system and the brakes with PITLOCK, so that the valuable individual parts are also secured against theft.

We would be happy to receive additional hints from you.

Do standard lengths suit my bicycle?

The Pitlock standard axles replace customary quick releases and are suitable for most bicycles. Racing bikes are special and not a standard. Since race bikes are thinner it results that the axles protrude unfortunately.

Even though we offer a broad range of several axle lengths, we are not able to cover all sizes. At best you measure the axle first, or you contact us for our advice.

The axle thread can only be shortened with the help of a hacksaw.

Attention: Please be very careful when shortening the axle.

EIn case the axle thread protrudes the security rings for approximately 5 mm it is possible to install our elegant end caps.

How much does PITLOCK weigh?

A saddle axle SA 33 with closure weighs approximately 25 gr.

A front wheel axle VA 119 with closure weighs approximately 41 gr.

TA rear wheel axle HA 155 with closure weighs approximately 47 gr.

A Pit key weighs approximately 11 gr.

A set 02 with packing weighs approximately 176 gr.

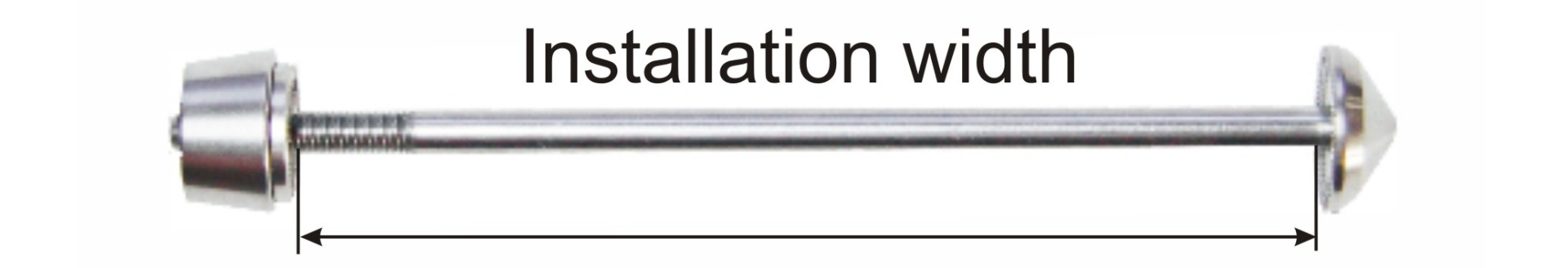

What does installation width mean?

For us the max. installation dimension is = installation width, the clamping dimension of the outer edges.

Since not only the installation width of the hub, but also the dropout of the frame are added, the clamping widths always differ depending on the frame.

Example:

You have an installation width of 113 mm.

Our axle names are also the max. installation widths.

The VA 119 has a min. installation width of 104 mm to max. 119 mm, length of the entire axle 129 mm.

Meaning that the VA 119 fits here.

Can I use PITLOCK for horizontal dropouts?

Horizontal dropouts with solid axles can be secured with Pitlock.

When it comes to quick release hubs with horizontal dropouts we do not recommend PITLOCK, unless a chain tensioner is applied.

If you have horizontal dropouts on your rear wheel (horizontal and not closed at back), we dissuade to use the Pitlock system for quick releases. The holding force of the solid axle security systems (e.g. M10, SH38 and SH90) is sufficient, even for horizontal dropouts.

Usually almost all rear wheels are being constructed in vertical dropouts (opening diagonally towards the bottom). In this case the installation of PITLOCK works without any problems.

How do I secure my bicycle in case I have a quick release lever in the front and a solid axle in the back?

The Pitlock quick release backups and the Pitlock backups for solid axles can not be produced to lock simultaneously due to the fact that the thread sizes differ from each other. Therefore the bigger coded nuts require a bigger PIT key to lock and unlock.

So, in case you have both types of hubs on your bicycle you need to secure with two different codenumbers.

How much are 10 Nm?

Rule of thumb:

Tighten the coded nut by hand using the PIT key. Then turn another 1 -1,5 rotations using a different tool.

All keys and the code card lost

Not good at all!

This problem can only be resolved in exceptional cases and by your local bikeshop. The coded nut and copies of your ID and of a buying receipt are required for the code determination and the reproduction of the Pit-Key.

The code determination has a cost of 8€.

Please try to avoid this case!

How do I open a coded nut correctly?

Place the correct PIT on the coded nut.

Now press the PIT and unscrew at the same time (just as when openening a child-proof cap on a medicine bottle).

This unlocks the spring washer from the grooves of the coded nut.

Can I purchase Pitlock directly from the manufacturer?

Generally we recommend to contact bicycle stockists since they provide the best service.

Since some dealers have problems fulfilling specific customer wishes or have problems ordering directly, it is also possible to order via the PITLOCK online store.

How do I install the spiral springs of the quick-release skewer with PITLOCKs?

These have to be completely removed with the quick release skewers.

Please do not install with PITLOCK securing devices.

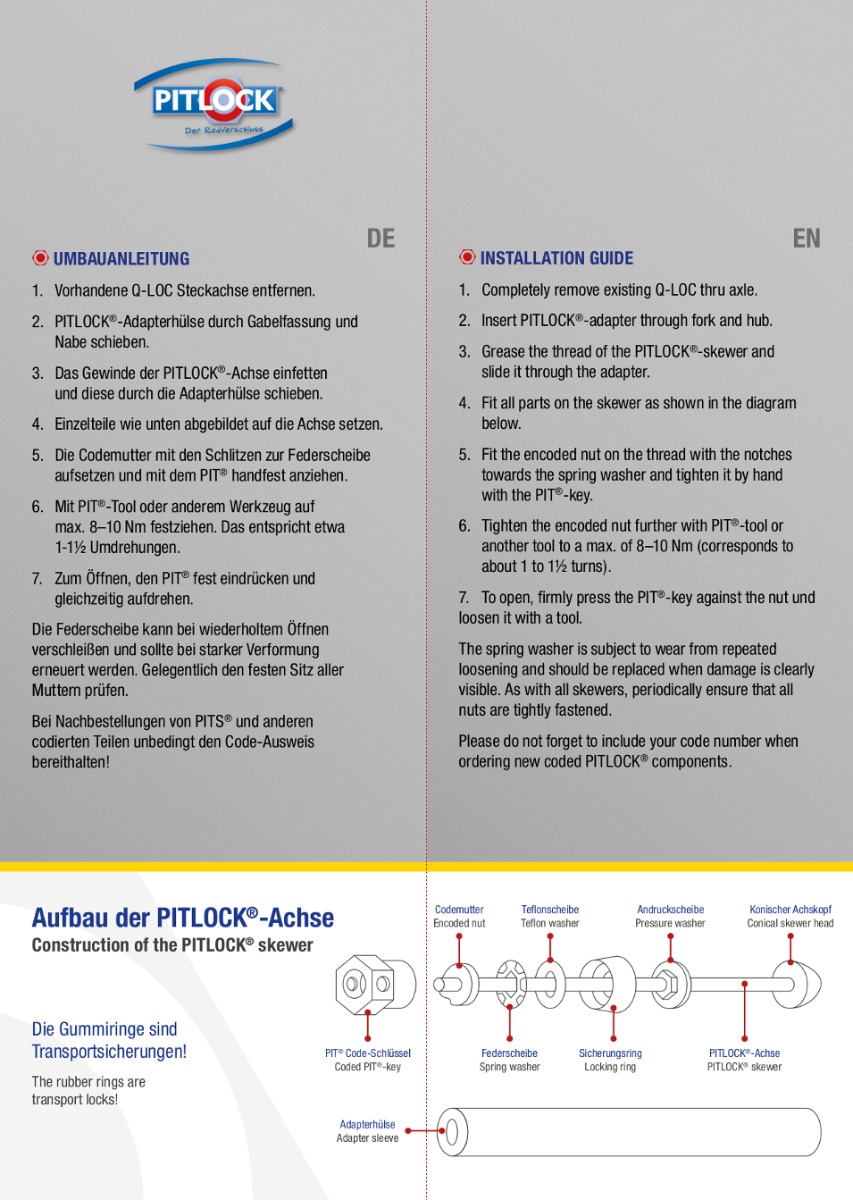

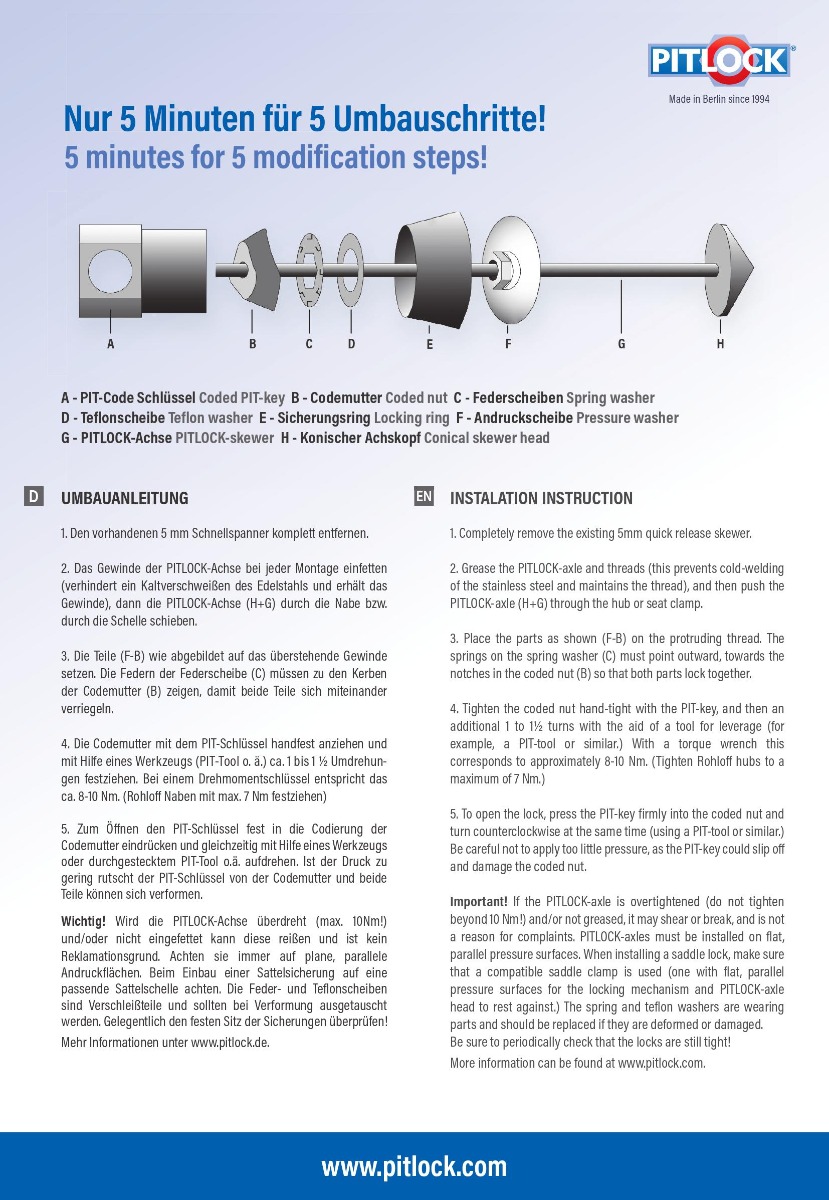

Conversion instructions

Installation Guide Solid Axles

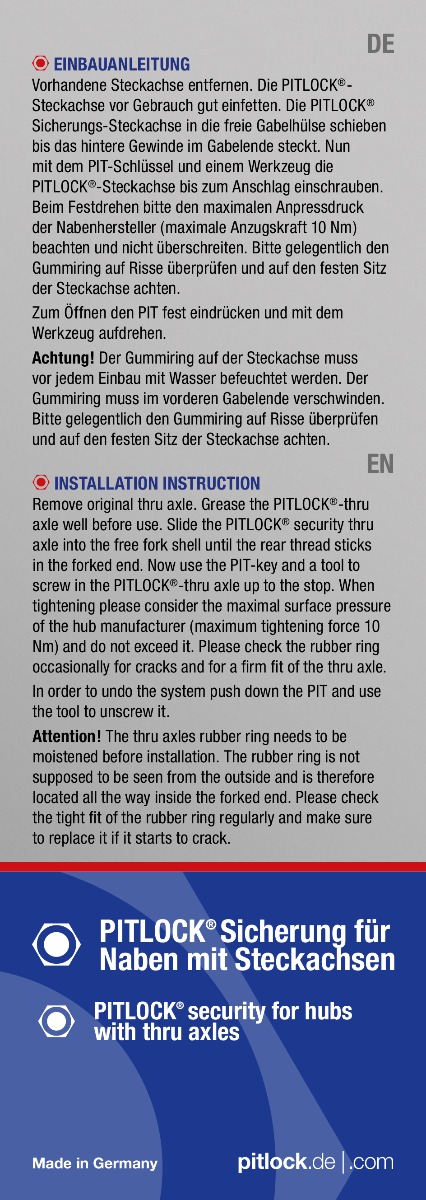

Thru Axle Conversion instruction

Installation guide quick release protection

If you have horizontal dropouts on your rear wheel (horizontal and not closed at back), we dissuade to use the Pitlock system for quick releases. The holding force of the solid axle security systems (e.g. M10, SH38 and SH90) is sufficient, even for horizontal dropouts.

Usually almost all rear wheels are being constructed in vertical dropouts (opening diagonally towards the bottom). In this case the installation of PITLOCK works without any problems.

The axles diameter is 5 mm. The M6 code bolts diameter is 6 mm.

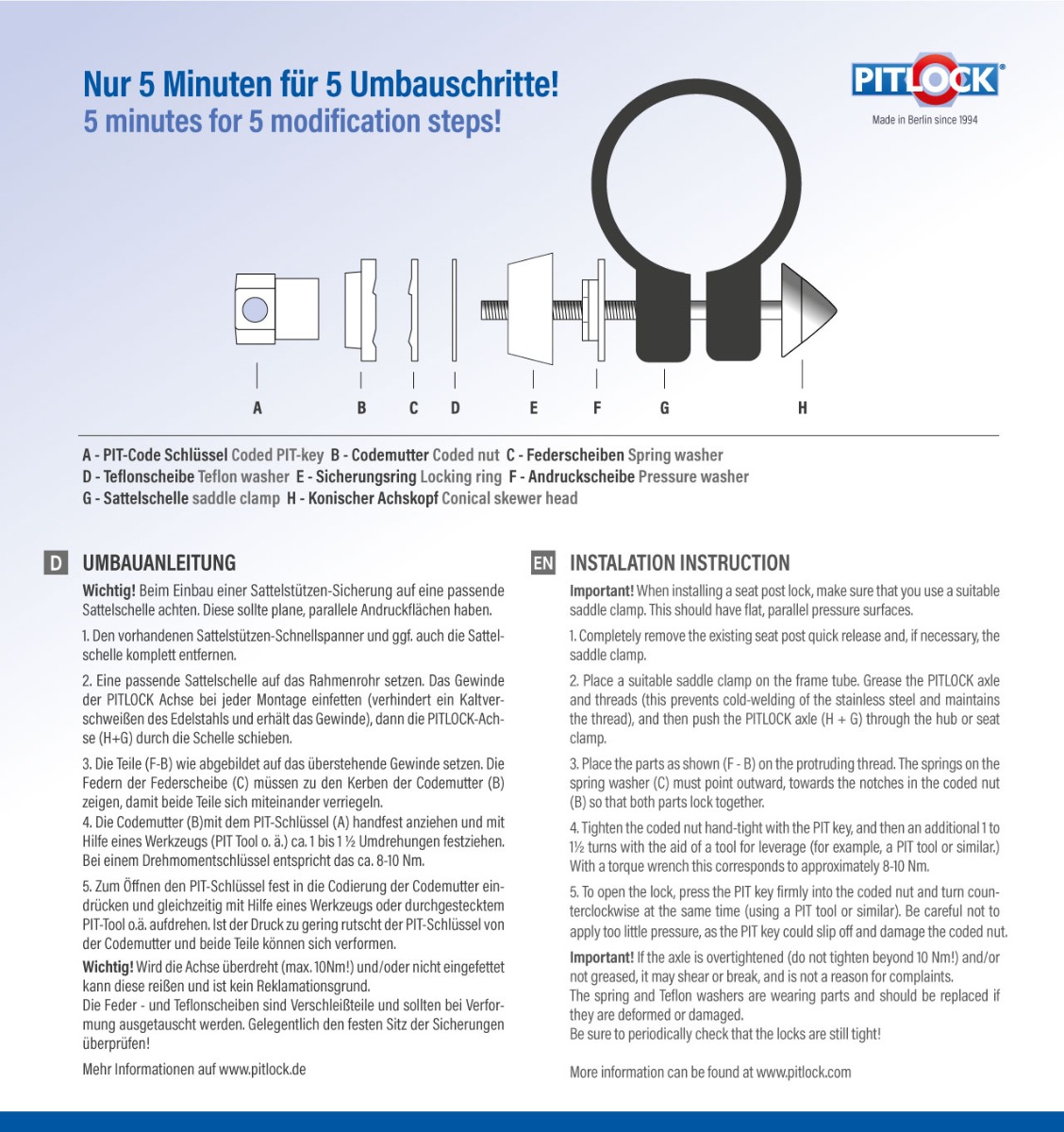

Assembly details by the manufacturer – see the PICTURE below.

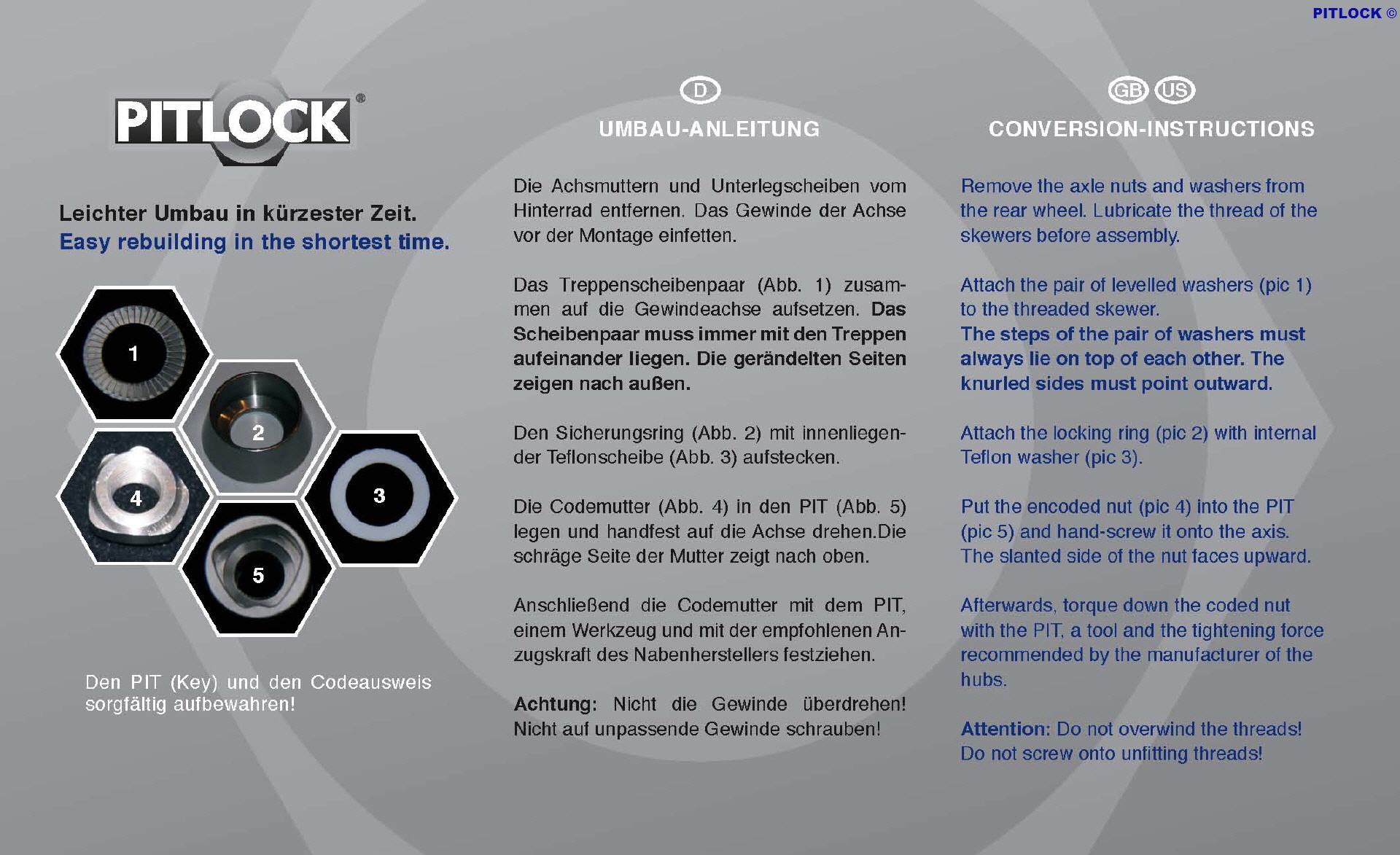

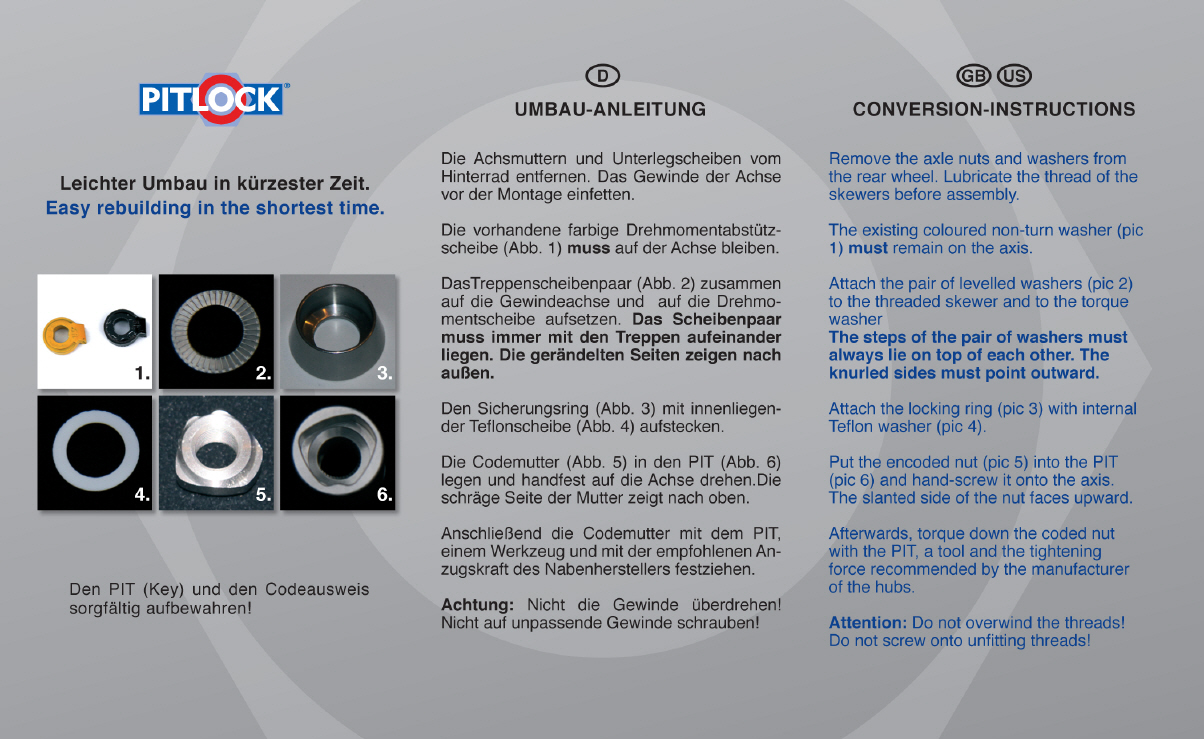

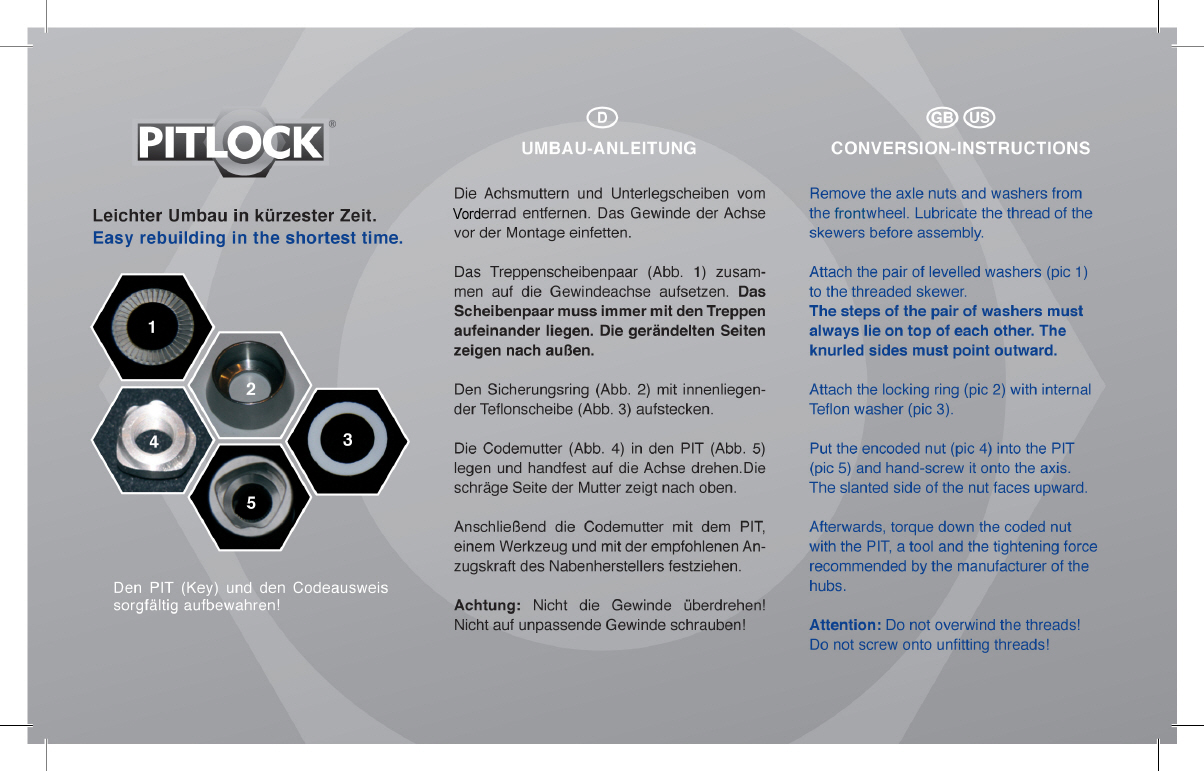

The Pit:

The Pit is an inside coded key to open and close the coded nut in the plug. In case of loss pleasereorder via our homepage or contact a specialist bicycle shop near you.

The coded nut:

The coded nut is screwed upon the axle using some grease. It is the matching counterpart of the PIT and locks the axle.

The spring washer:

It locks the coded nut and therefore prevents it from being unscrewed accidentally. The spring washers must be assembled together with the springs, pointing to the direction of the coded nut.

Teflon ring:

The Teflon ring pads the distance to the inside and prevents the parts from sticking together.

The security ring:

The security ring encloses the coded nut with the entire closure and protects against unauthorized opening.

Pressure washer:

Connects the coded nut and the spring washer with the contact surface on the bicycle frame.

The PITLOCK axle:

Prevents the conical head end to be opened with pliers.

Pit-cap:

To complete the locks in a visually attractive way we recommend assembling protective caps upon the PITLOCK closures. In case the thread axle protrudes the security ring a cap can complete the closure. Push the enclosed rubber ring upon the thread axle to prevent the caps from falling off unintentionally. Screw the cap upon the remaining protruding part of the thread manually until the security ring seals the cap – done.

IMPORTANT:

Keep in mind to grease the side of the thread before installation. When using Rohloff gear hubs with quick releases a maximal torque of 7 Nm must not be exceeded.

Correct Assembly of Calliper Brakes

The PITLOCK security M6 for brakes needs enough space around the brakes for installation since the security ring needs to be installed as well.

The security ring has a diameter of circa 19 mm and a height of circa 10 mm.

Calliper brakes and disc brakes can be secured with PITLOCK M6 security screws.

The PITLOCK brake security consists of either a M6 codescrew (M6) or two M6 codescrews (M6 double) with the appropriate locking components.

The brake is secured sufficiently if one side is secured in the front and the same side in the back.

Postmount adapter have to be secured seperately with PITLOCK M6 screws if necessary.

For brakes with quick release levers the PITLOCK security screws are installed on the side without the quick release.

Additionally it is also possible to use locking fluid. Drip a little locking fluid on the thread of the PITLOCK M6 screw and tighten it firmly.

If the height of just one washer is not sufficient, just assemble another one.

How do I open the coded nut correctly?

Place the correct PIT on the coded nut. Now press the PIT and unlock the system (see childproof cap on a medicine bottle). This way the spring washer will come off the grooves of the coded nut.

Quick release skewer conversion

pair of chain tensioners

NOTE:

In the case of gear hubs with a hollow axle for quick release skewers - in conjunction with horizontal dropouts - there may be small displacements of the rear wheel, if the PitLOCK axle has not been tightened sufficiently.

Corrective action:

Fix the ends of the axles in place on both sides with a chain tensioner. The chain tensioners now support the holding force.

Under no circumstances should you tighten the nuts with a higher torque than 7Nm. Otherwise the function of the Rohloff hub will be endangered.

How do I install the spiral springs of the quick-release skewer with PITLOCKs?

These have to be completely removed with the quick release skewers. Please do not install with PITLOCK securing devices.

How much Nm are needed to tighten the Pitlock system?

We recommend to tighten the quick-releases with 7-10 Nm and the solid axles with up to 30 Nm. But please always note the manufacturer specifications of the hubs.

Axles

Ripped PITLOCK Axle

In most cases PITLOCK´s stainless steel axles rip if they are pulled too tightly during the installation or if the installation guide has not been noted.

The axles can be pulled up to 7-10 Nm. At best the coded nut is tightened by hand and a tool is used for another 1-1½ rotations. Thus the coded nut should be tightened sufficiently.

Pitlock is made of certified stainless steel and has been tested by Velotech.

The following instructions should be noted:

- The threaded ends of the PITLOCK axles need to be greased before every installation.

- The contact surfaces need to be plane.

- All parts need to be installed in the right order.

- The saddle clamp has to be suitable for PITLOCK, with plane contact surfaces for the PITLOCK axle.

If these instructions are disregarded it is more likely that the axle rips.

Spare parts, further sets and spare keys can be reordered easily via our PITLOCK online shop ( www.pitlock.de) or a specialist bicycle retailer.

Check also:

https://www.pitlock.de/de/shop/nachkauf/ohne-verschluss.html

In case you would like to claim the axle, we give you the opportunity to send it to us incl. the purchase receipt and reliably enclosed.

Hence we will check the parts and may possibly provide replacement.

Installation Widths & Axle Lengths - How do I measure the correct length?

What is the installation width?

The installation width is the distance between the outer surfaces of a saddle clamp and can be measured on the bicycle dropouts of the wheels. The axle is approximately 10-12 mm longer, as the pressure head and the extra amount for the coded nut with all of the locking elements have to be added. So you only have to measure the outer surfaces of the dropouts.

Standard axles:

- VA 119 minimal installation width 104 mm to maximal installation width 119 mm, length of the entire axle 129 mm.

- HA 155 minimal installation width 140 mm to maximal installation width 155 mm, length of the entire axle 169 mm.

- SA/LA 33 minimal installation width 18 mm to maximal installation 33 mm, length of entire axle 43 mm.

- SA/LA 23 minimal installation width 8 mm to maximal installation 23 mm, length of entire axle 33 mm.

Longer Pitlock axles:

- VA 130 minimal installation width 105 mm to maximal installation width 130 mm, length of the entire axle 140 mm.

- HA 170 minimal installation width 155 mm to maximal installation width 170 mm, length of entire axle 180 mm.

- SA/LA 45 minimal installation width 30 mm to maximal installation width 45 mm, length of the entire axle 55mm.

- SA/LA 60 minimal installation width 45 mm to maximal installation width 60 mm, length of the entire axle 70 mm.

Universal axis 240 minimal installation width 10 to maximal 240 mm with continuous axle thread.

Can PITLOCK axles be shortened?

Stainless steel solid axles can carefully be shortened with a steel saw. Sanding the end a bit after cutting will leave the thread functioning fine.

Why can I not tighten the PITLOCK axle?

WHEEL

Are the spiral springs of the quick release skewer installed with PITLOCK?

Are the spiral springs of the quick release skewer installed with PITLOCK?

Does the hub slightly protrude the dropouts?

Check this using your fingers. In case it protrudes, the pressing surface is not plane anymore.

Solution:

If the hub protrudes, shorten the ends of the axle tube carefully with a file. Please be careful when doing so and do not shorten more than 0.5mm.

Now you can install the wheel again with PITLOCK.

Ensure a tight fit - done!

Rohloff Solid Axles

Important

The protruding thread should extend about 14 mm out of the dropout in order to securely install PITLOCK. In case the protruding thread is too short, it is necessary to use an axle stub with a long threaded axle (available from Rohloff).

Available from Rohloff.

Art. no. at Rohloff: 8235L; axle plate TS OEM SOLID AXLE CONVERSION

If your bicycle has solid axles, you can use PITLOCK´s set M10 double or single.

Please make sure that the threads protrude far enough and that there is enough space for the security ring, so that the locking elements can be assembled correctly. Please also make sure to grease the thread before the assembly.

QUICK RELEASE SKEWERS CONVERSION

pair of chain tensioners

NOTE:

In the case of gear hubs with a hollow axle for quick release skewers - in conjunction with horizontal dropouts - there may be small displacements of the rear wheel, if the PitLOCK axle has not been tightened sufficiently.

Corrective action:

Fix the ends of the axles in place on both sides with a chain tensioner. The chain tensioners now support the holding force.

Under no circumstances should you tighten the nuts with a higher torque than 7Nm. Otherwise the function of the Rohloff hub will be endangered.

Have the PITLOCK axles been tested for extreme loads?

No!

The PITLOCK axles have been tested by Velo-Tech for normal conditions in road traffic.

After final approval the security systems have been put on the market.

We do not recommend to do neither downhill racing nor high jumps with a bicycle fitted with PITLOCK.

Dimensions

Pit Ahead Alu Plug / Dimensions

| Nominal size | Base diameter | Head diameter | Height |

|---|---|---|---|

| 1 inch (undersize) | 7/8 inch/ 22 mm | 1 1/8 inch / 28,5 mm | 7/16 inch / 11,4mm |

| 1 1/8 inch (standard) | 7/8 inch / 23 mm | 1 1/4 inch / 32 mm | 7/16 inch / 11,4 mm |

| 1 1/4 inch (outsize) | 1 1/8 inch/ 28,2 mm | 1 3/8 inch / 35 mm | 7/16 inch / 11,4 mm |

Installation Widths & Axle Lengths - How do I measure the correct length?

What is the installation width?

The installation width is the distance between the outer surfaces of a saddle clamp and can be measured on the bicycle dropouts of the wheels. The axle is approximately 10-12 mm longer, as the pressure head and the extra amount for the coded nut with all of the locking elements have to be added. So you only have to measure the outer surfaces of the dropouts.

Standard axles:

- FW 119 minimal installation width 104 mm to maximal installation width 119 mm, length of the entire axle 129 mm.

- RW155 minimal installation width 140 mm to maximal installation width 155 mm, length of the entire axle 169 mm.

- SP/HA 33 minimal installation width 18 mm to maximal installation 33 mm, length of entire axle 43 mm.

Special axles:

- FW 130 minimal installation width 105 mm to maximal installation width 130 mm, length of the entire axle140 mm.

- RW 170 minimal installation width 155 mm to maximal installation width 170 mm, length of entire axle 180 mm.

- SP/HA 45 minimal installation width 30 mm to maximal installation width 45 mm, length of the entire axle 55mm.

- SP/HA 60 minimal installation width 45 mm to maximal installation width 60 mm, length of the entire axle 70 mm.

- SP/HA 23 minimal installation width 8 mm to maximal installation width 23 mm, length of the etire axle 33 mm.

Universal axis 240 minimal installation width 10 to maximal 240 mm with continuous axle thread, lenght of entire axle 250 mm.

All axles have a thread length of 25 mm.

How much are 10 Nm?

Rule of thumb:

Tighten the code nut by hand using the PIT key. Then turn another 1 -1,5 rotations using a different tool.

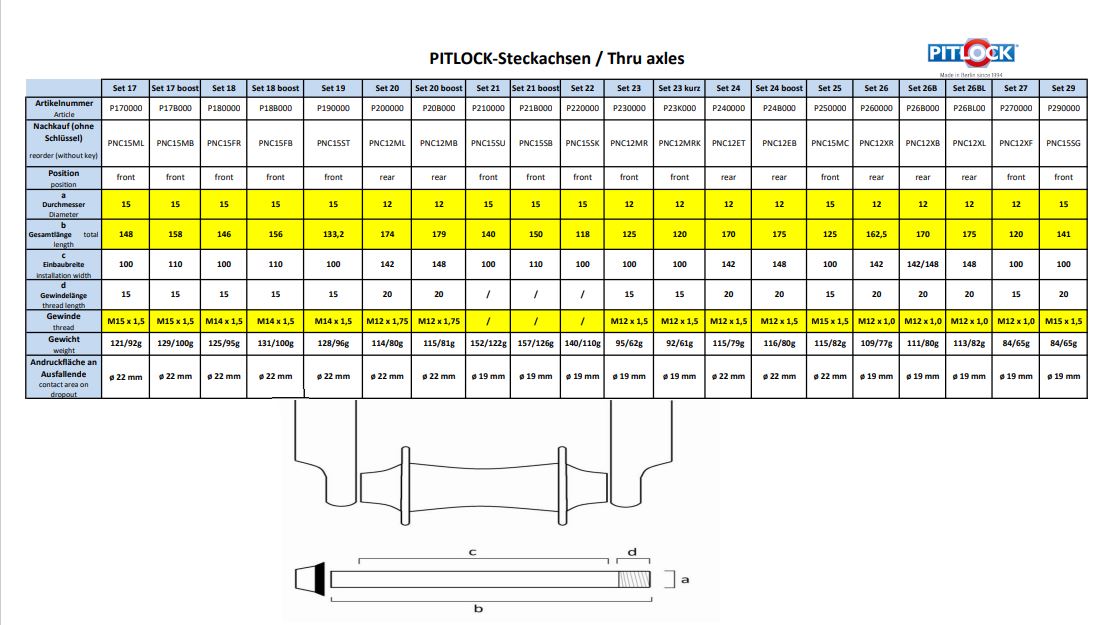

Thru axles

Pitlock offers thru axles for different bike models. You'll find the specific details on the different product pages. To be sure that the Pitlock axle fits on your bike please check the dimensions of your original axle. Following chart shows the different Pitlock thru axle sets and the exact axle dimensions:

Tighten the code nut by hand using the PIT key. Then turn another 1 - 1,5 rotations using a different tool.

Saddle

Saddle Security

- Secure the seat tube

In order to secure the seat tube, please order Set 06

When installing the seat post security, please make sure that the outer pressure surfaces of the saddle clamp are both plane and parallel.

In case you don´t have a fitting clamp on your bike, it is possible to order one here.

Which saddle clamp do I need?

Just measure the outer diameter of the bicycle frame.

28.6 mm for seat tubes with a diameter of 27.5 - 28.8 mm

30.00 mm - 34.9 mm saddle clamp with spacer

31.8 mm for seat tubes with a diameter of 30.5 - 32 mm

34.9 mm for seat tubes with a diameter of 33.6 - 35 mm

36.4 mm - 40 mm saddle clamp with spacer

40 mm for seat tubes with a diameter of 38.7-40.2 mm

Information Concerning the Seat Post Security

Please note:

If the seat post does not have a separate clamp, but only eyelets welded on the bicycle frame, enough plane pressure surface needs to be available to install the Pitlock closure.

Since the eyelets of the bicycle frame cannot be clamped, just as the ones of an additional plane saddle clamp, an optimal connection between the two pressure surfaces is not possible.

The seat tube is moving slowly back into the frame tube

Release the PITLOCK saddle axle, then the seat tube and grease the opening in the bicycle frame thoroughly. Then re-assemble all the parts and tighten them. If the diameter of the seat tube is too thin, only the upper edge of the frame will apply pressure during the tightening process. The necessary surface pressure cannot be produced. In this case please replace the thin seat tube with a different one having the appropriate diameter which fits without any play - this will then no longer slide downwards.

Trailers

Can I secure my bicycle trailer (for children) with PITLOCK?

PITLOCK has only been tested for the Weber E trailer coupling.

Possibly PITLOCK is not suitable for other trailer couplings, especially if the trailer load is attached to the PITLOCK axle.

The trailer load is not supposed to lie upon the PITLOCK axle.

https://www.pitlock.de/tipps/weber-anhaenger/index.html

For the Weber E trailer coupling we have different lengths of rear wheel axles in our product range:

- HA 155 standard

- HA 170 oder

- universal axle 240

Can I secure the BobYak trailer?

PITLOCK is only able to secure the wheel.

PITLOCK can not secure BobYak trailer couplings since they are constructed differently.

Bicycle Trailers/ Weber E Trailers

Weber Trailers

Our PITLOCK system has been tested intensively for suitability by WEBER TECHNIK:

WEBER E-coupling and PITLOCK rear wheel axle, the coded nut tightened with 8-10 Nm, load simulation of 80 kg set on the trailer.

The result of this test series demonstrated:

The experiment was supported by all components involved.

Note:

The PITLOCK axle is not supposed to be bent and the locking side needs to have a plane fit on the frame (dropout).

The correct fit of the PITLOCK security (as with the quick release) should be checked regularly.

When assembling it is necessary to ensure that the WEBER multi-tooth element of the anti-rotation device is completely pressed into the base sheets of the coupling.

NOTE FOR LONGER REAR WHEEL AXLES

If the rear wheel standard length of 155 mm (installation width) is not sufficient, we also offer longer rear wheel axles of 170 mm and 240 mm.

Orders

How do I order a replacement Pit-key?

Via our online shop. Open the “repurchase” category and select "repurchase Pit-key".

Choose either the key for M5 (small) or for solid axles (big).

How do I order several sets with the same coding?

Sets within an order are only delivered to consumer with the same code. If everything is to be delivered with the same key or if you want different coding, please note it in the "note field in the shopping cart"!

As a new customer, how do I order a set and do additional orders (the code field is mandatory) with the same coding?

Sets of the same order are usually delivered with the same coding.

If you have any questions, please call us: D +49 (0) 30 6112092

Shipping Charges

- For end consumers:

- Shipping to Germany: € 5,90

- Shipping to other countries in the EU: € 11,50

- Shipping to countries outside the EU depending on order value:

- Orders up to 100 €: € 15,90

- Orders from 100 €: € 25,90

- For dealers:

- Shipping charges are determined depending on the weight and the country.

Return Delivery

Please note that neither repeat nor replacement orders with a personal coding can be send back to you since they are customized.

For further information please check out ourterms and conditions.

Buy replacements

How long does the production and delivery of coded replacement parts / keys take?

One day.

The coded parts will be delivered one day after payment.

How do I order a replacement Pit-key?

Via our online shop. Open the “repurchase” category and select"repurchase Pit-key"".

Choose either the key for M5 (small) or for solid axles (big).

I have lost my code card!

You have the possibility to send in the Pit-key (please enclose it reliably).Then we can determine your codenumber.

The determination of your code costs 8 € incl. code card. The delivery costs are calculated depending on the country you live in.

Advice from a biker

I have lost my code card!

Hello again,

After riding approximately 2,000 km since summer, including an extensive tour of the Baltic, here as promised is my summary of the topic of talcum powder on slippery seat posts: my seat post has not moved 1 mm more into the seat tube since the talcum powder cure! Certainly highly recommended! The seat tube only has to be moderately greased (in order to prevent corrosion), but not the post! There is then enough contact pressure and there are no more problems. So please consider putting the advice on your page under "Further Tips". Thanks once more for your goodwill concerning the reordering of my screwed up clamp axle and all the best to you and your company. Best regards from Leipzig, Stephan

A short postscript: the advice with the talcum powder cure only applies in my test together with the use of a distance sleeve to adapt various seat post tube diameters to the seat tube of the frame. My test only applies to this combination. The inside of the distance sleeve and the seat post tube are not greased (but the outside of the distance sleeve and the seat tube are) and instead covered with talcum powder. That will definitely work. I did not mention that explicitly, but it was clear from my first “talcum e-mail". So now everything must have been explained in a plausible way. A simple solution to a problem that can really get on your nerves.

Best wishes, Stephan G.

Thru Axles

Measures

Pitlock offers thru axles for a variety of bike models. The exact details of each Pitlock thru axle can be found on the corresponding product page. To be sure the Pitlock axle fits on your bike, please compare the dimensions of the original thru axle qith the information given on our website. Here an overview on the different Pitlock thru axles:

If you are unsure about what thru axle you need, please use our help sheet for thru axles or the detailed overview of thru axles.

Set 17 (P170000 / Repurchase: PNC15ML)

| Position: | front wheel |

| Bycicle type: | Mountainbike |

| Compatibility: | Manufacturers who use the maxle standard are among others RockShox, Lauf, Whisky, Formula, Niner and Idworx. |

| Dimensions: | 15 x 148 mm, thread: M15 x 1,5 |

| Boost: | Set 17B (P17B000 / PNC15MB) 15 x 158 mm, thread M15 x 1,5 |

| Special features: | New idworx forks are made in the Boost-Standard with an installation width of 110 mm. Nevertheless the regular Pitlock Maxle thru axles fit with a total length of 148 mm. |

Set 18 (P180000 / Repurchase: PNC15FR)

| Position: | front wheel |

| Bycicle type: | Mountainbike |

| Compatibility: | FOX MTB forks with thru axle mount |

| Dimensions: | 15 x 146 mm, thread: M14 x 1,5 |

| Boost: | Set 18B (P18B000 / PNC15FB) 15 x 156 mm, thread M14 x 1,5 |

| Special features: | - |

Set 19 (P190000 / Repurchase: PNC15ST)

| Position: | front wheel |

| Bycicle type: | City / Trekking |

| Compatibility: | Stevens K1 rigid forks with thru axle mount |

| Dimensions: | 15 x 133,2 mm, thread: M14 x 1,5 / thread socket: 15 x 20 mm + 5 x 25 mm |

| Special features: | The set contains a threaded socket for the intake of the axle on the K1 fork, as the Stevens rigid fork does not provide a thread intake itself. |

Set 20 (P200000 / Repurchase: PNC12ML)

| Position: | rear wheel |

| Bycicle type: | Mountainbike, City / Trekking, Road / Cyclocross |

| Compatibility: | Compatible with frames with maxle mount on the rear dropouts. Manufacturers that use the Maxle standard on the rear wheel are among others Haibike, Kona, KTM, Trek, Niner. You can find a non exclusionary list with modelshere |

| Dimensions: | 12 x 174 mm, thread: 12 x 1,75 |

| Boost: | Set 20B (P20B000 / PNC12MB) 12 x 179 mm, thread: M12 x 1,75 |

| Special features: | Fittable on slightly shorter lengths in combination with special compensation washers. Washers available in the shop. |

Set 21 (P210000 / Repurchase: PNC15SU)

| Position: | front wheel |

| Bycicle type: | Mountainbike |

| Compatibility: | Suntour Forks with QLoc-System and dropouts with a width of 20 mm |

| Dimensions: | 15 x 140 mm |

| Boost: | Set 21B (P21B000 / PNC21SB) 15 x 150 mm |

| Special features: | The QLoc-System does not contain threads on the fork, but requires a lateral clamp on the side of the axle. The Pitlock Security is a clamp for a regular Pitlock axle with closure in an adapter sleeve of 15 x 140 mm. |

Set 22 (P220000 / Repurchase: PNC15SK)

| Position: | front wheel |

| Bycicle type: | City / Trekking |

| Compatibility: | Suntour Forks with QLoc-System and dropouts with a width of 10 mm |

| Dimensions: | 15 x 118 mm |

| Special features: | The QLoc-System does not contain threads on the fork, but requires a lateral clamp on the side of the axle. The Pitlock Security is a clamp for a regular Pitlock axle with closure in an adapter sleeve of 15 x 120 mm. |

Set 23 (P230000 / Repurchase: PNC12MR)

| Position: | front wheel |

| Bycicle type: | Road |

| Compatibility: | Manufacturers who use the maxle standard are among others Enve, Merida, Bianchi, Whisky, DT Swiss, Parlee and Ridley |

| Dimensions: | Set 23 12 x 125 mm, thread: 12 x 1,5 Set 23K (P23K000 / PNC12MRK) 12 x 120 mm, thread: 12 x 1,5 |

Set 24 (P240000 / Repurchase: PNC12ET)

| Position: | rear wheel |

| Bycicle type: | MTB, City/Trekking, Road/CC |

| Compatibility: | Frames with standard 12 x142 mm or 12 x 148 mm E-Thru mount on the rear dropout. |

| Dimensions: | 12 x 170 mm, thread: 12 x 1,5 |

| Boost: | Set 24B (P24B000 / PNC12EB) 12 x 175 mm, thread: 12 x 1,5 |

| Special features: | Fittable on slightly shorter lengths in combination with special compensation washers. Washers available in the shop. |

Set 25 (P250000 / Repurchase: PNC15MC)

| Position: | front wheel |

| Bycicle type: | Road / Gravel / CC |

| Compatibility: | Fixed forks with narrow dropouts (max 13 mm) and 15 x 100 mm Maxle mount. |

| Dimensions: | 15 x 125 mm, thread: M15 x 1,5 |

Set 26 (P260000 / Repurchase: PNC12XR)

| Position: | rear wheel |

| Bycicle type: | Road / MTB |

| Compatibility: | for X-12 mount and Canyon frames |

| Dimensions: | 12 x 162,5 mm, thread: 12 x 1,0 |

| Boost: | Set 26B (P26B000 / PNC12XB) 12 x 170 mm, thread: 12 x 1,0 Set 26BL (P26BL00 / PNC12XL) 12 x 175 mm, thread: 12 x 1,0 |

| Special features: | - |

Set 27 (P270000 / Repurchase: PNC12XF)

| Position: | front wheel |

| Bycicle type: | Road / CC |

| Compatibility: | for X-12 mount |

| Dimensions: | 12 x 120 mm, thread: 12 x 1,0 |

| Special features: | - |